1.2738 (40CrMnNiMo8-6-4)

It is a plastic mold steel supplied pre-hardened (30-33 HRC). The difference between this and 1.2311 and 1.2312 is the Nickel element in its structure. As a result, its polishing ability is better compared to these two materials. Thanks to its pattern capability, wear resistance, and polishability, it has a wide range of uses in plastic molds. It is recommended to be used in its delivery hardness. It is suitable for nitration and surface coating processes. It's a weldable material.

| C | Si | Mn | P Max | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0,35 - 0,45 | 0,20 - 0,40 | 1,30 - 1,60 | 0,003 | 0,003 | 1,80 - 2,10 | 0,15 - 0,25 | 0,90 - 1,20 |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2738 | P20+Ni | 40CrMnNiMo8-6-4 |

APPLICATION AREAS

- Plastic injection molds

- Extrusion molds for non-corrosive plastics

- Large-scale bumper molds

- Plastic pressing and compression applications

- Carriers of metal injection molds

PHYSICAL PROPERTIES

| Temperature | 20 °C | 350 °C | ||

| Thermal Conductivity | 39,50 | 39,10 | ||

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 11,80 | 12,50 | 13,10 | 13,30 |

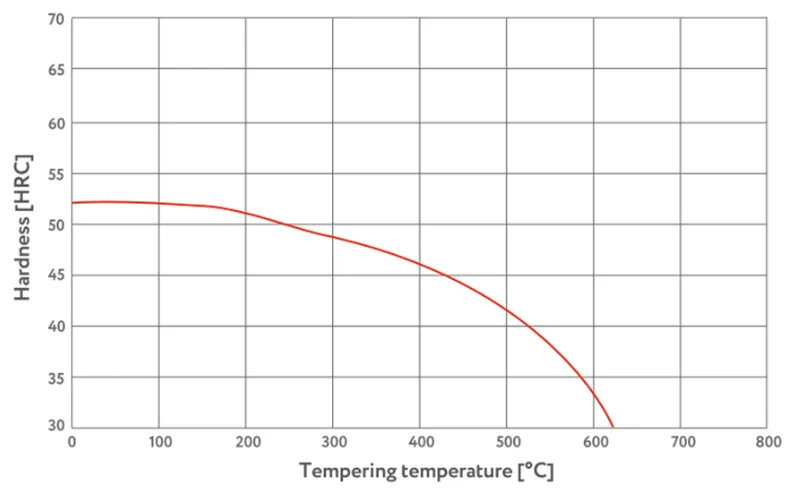

TEMPERING