1.2738 HH (40CrMnNiMo8-6-4)

It is a plastic mold steel supplied pre-hardened (33-38 HRC). The difference between this and 1.2311 and 1.2312 is the Nickel element in its structure. As a result, its polishing ability is better compared to these two materials. Thanks to its pattern capability, wear resistance, and polishability, it has a wide range of uses in plastic molds. The only difference from 1.2738 material is its hardness. It's preferred in applications where higher wear resistance is needed. It's suitable for nitration and surface coating processes.

| C | Si | Mn | P Max | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0,33 - 0,45 | 0,20 - 0,40 | 1,30 - 1,60 | 0,003 | 0,003 | 1,80 - 2,10 | 0,15 - 0,25 | 0,90 - 1,20 |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2738 HH | P20+Ni | 40CrMnNiMo8-6-4 |

APPLICATION AREAS

- Plastic injection molds

- Extrusion molds for non-corrosive plastics

- Large-scale bumper molds

- Plastic pressing and compression applications

- Machine parts, wear plates

PHYSICAL PROPERTIES

| Temperature | 20 °C | 350 °C | ||

| Thermal Conductivity | 39,50 | 39,10 | ||

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 11,80 | 12,50 | 13,10 | 13,30 |

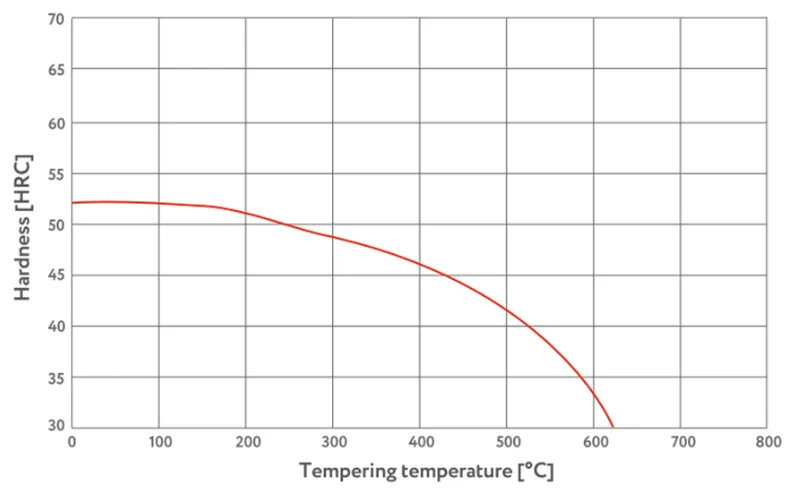

TEMPERING