1.2312 (40CrMnMoS8-6)

It is a plastic mold steel supplied pre-hardened (30-33 HRC). Due to the sulfur element in its composition, its machinability is better than 1.2311 and 1.2738. However, due to sulfur, its pattern capability and polishability are poor. For mold cores where a shiny product surface is desired, 1.2738 should be preferred. It is a material suitable for nitration. The recommended usage hardness is the delivery hardness.

| C | Si | Mn | P Max | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0,33 - 0,45 | 0,30 - 0,50 | 1,40 - 1,60 | 0,003 | 0,05 - 0,10 | 1,80 - 2,00 | 0,15 - 0,25 | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2312 | P20+S | 40CrMnMoS8-6 |

APPLICATION AREAS

- Plastic injection molds

- Rubber molds

- Metal injection bases and mold sets

- Machine parts and fixture components

PHYSICAL PROPERTIES

| Temperature | 20 °C | 350 °C | ||

| Thermal Conductivity | 39,60 | 39,20 | ||

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 12,20 | 12,70 | 13,20 | 13,60 |

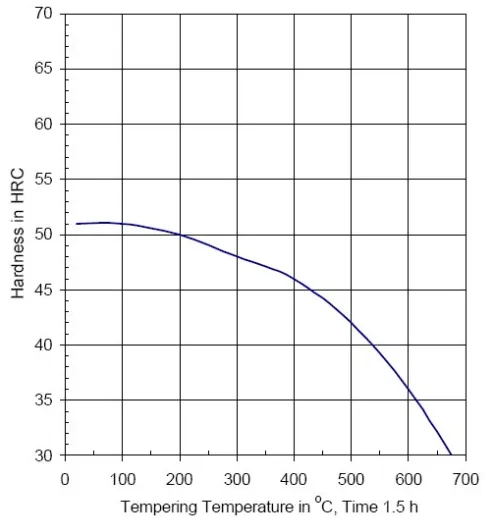

TEMPERING