1.2085 (X33CrS16)

It is a plastic mold steel that exhibits stainless properties due to its high Cr content. Supplied pre-hardened (280-325 HBW), the machinability of 1.2085 material is quite good. It is especially preferred in injection molds for plastic products that come into contact with food or in mold bases for molds where corrosion resistance is crucial (like PVC molds). Its stainless property is better than that of the 1.2083 grade.

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0,28 - 0,38 | 0,30 - 1,00 | 1,00 - 1,40 | 0,03 | 0,05 - 0,10 | 15,00 - 17,00 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2085 | 420 FM | X33CrS16 |

APPLICATION AREAS

- Plastic injection molds

- Plastic extrusion molds

- Mold bases

PHYSICAL PROPERTIES

| Temperature | 20°C | |||

| Thermal Conductivity | 24,30 | |||

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 11,00 | 11,10 | 11,40 | 11,70 |

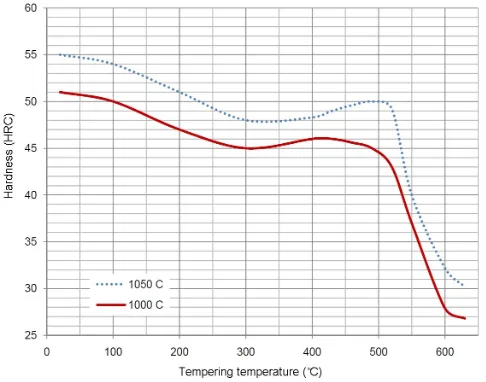

TEMPERING