1.2316 (X38CrMo16)

Due to the high Cr (chromium) content in its composition, it exhibits corrosion resistance and is used as a plastic mold steel. 1.2316 is supplied in a pre-hardened state (~ 280-320 HBW). It contains more chromium compared to 1.2083 and therefore shows better corrosion resistance. It has good polishability. It's an ideal core and base material for plastic injection and plastic extrusion molds that require corrosion resistance. It is frequently used in molds for corrosive plastics like PVC. Additionally, it is preferred in some machine equipment in the food industry.

| C | Si | Mn | P Max | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0,33 - 0,45 | 1,00 | 1,00 - 1,50 | 0,003 | 0,003 | 15,50 - 17,50 | 0,80 - 1,30 | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2316 | - | X38CrMo16 |

APPLICATION AREAS

- Plastic injection molds

- Plastic extrusion molds

- Mold bases

PHYSICAL PROPERTIES

| Temperature | 20-100 °C | 350 °C | ||

| Thermal Conductivity | 19,60 | 21,10 | ||

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 10,30 | 10,80 | 11,20 | 11,60 |

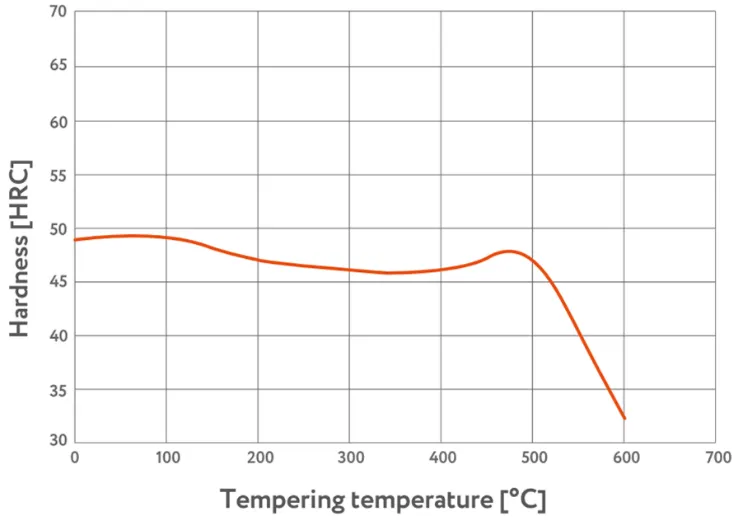

TEMPERING