1.2714 QT (55NiCrMoV7)

It is a hot work steel with nickel alloy in its structure, possessing high toughness. Due to its high toughness, it is one of the most consumed materials in hot forging molds. Especially in hammer forging, it exhibits high resistance to breaking. 1.2714 is supplied both pre-hardened (QT 38-42 HRC) and soft annealed (220-250 HBW). Due to its low hardness, a very high product count should not be expected. It can be used with nitration treatment for surface wear resistance.

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 0,50 - 0,60 | 0,10 - 0,40 | 0,25 - 0,50 | 0,65 - 0,95 | 0,025 | 0,005 | 0,80 - 1,20 | 0,45 - 0,55 | 0,07 - 0,12 | 1,50 - 1,80 |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2714 | 6F3 | 55NiCrMoV7 |

APPLICATION AREAS

- Core in hot forging molds

- Mold carriers in hot forging molds

- In hammers

- In aluminum extrusion tools

- In hot shear blades

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 25,60 | 28,40 | 29,40 | |

| Temperature | 20-100°C | 20-300°C | 20-500°C | 20-700°C |

| Thermal Expansion | 10,80 | 12,30 | 13,00 | 13,50 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 750-800 | In Furnace |

| Stress Relieving | 600-650 | In Furnace |

| Hardening | 1020-1060 | Pressurized gas, air, oil |

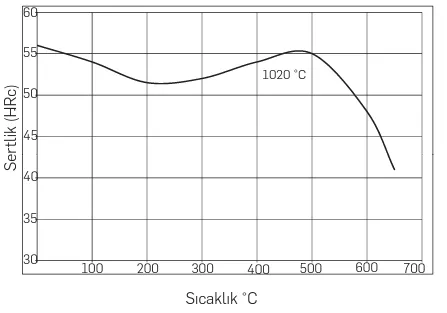

TEMPERING