DAC Magic

DAC MAGIC, with its high temper resistance and high toughness, primarily extends the mold life in all hot work applications, including metal injection molds, thereby reducing the part cost. In high-pressure aluminum, magnesium, and brass injection molds; hot forging molds; extrusion molds; glass fiber reinforced plastic injection molds requiring long life; cold work applications with chronic fracture problems; and thick sheet cutting blades, it makes a significant difference compared to conventional hot work steels. DAC MAGIC is the ideal material for those wanting to get high performance from metal injection molds.

CHEMICAL COMPOSITION (%)

| Cr-Mo-V Alloy Patent Material |

STANDARD EQUIVALENTS OF THE MATERIAL

| DAC MAGIC |

APPLICATION AREAS

- Metal injection molds

- Hot forging molds

- Hot cutting blades

- Industrial blades

- Plastic molds

- Mold parts with chronic fracture problems

PHYSICAL PROPERTIES

| Temperature | 20°C | 200°C | 400°C | 600°C |

|---|---|---|---|---|

| Thermal Conductivity | 25,70 | 30,90 | 34,80 | 35,80 |

| Temperature | 20-200°C | 20-400°C | 20-600°C | |

| Thermal Expansion | 11,30 | 12,30 | 13,10 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 820-870 | In Furnace |

| Stress Relieving | 880 | In Furnace |

| Hardening | 1010-1030 | Pressurized gas, air, oil |

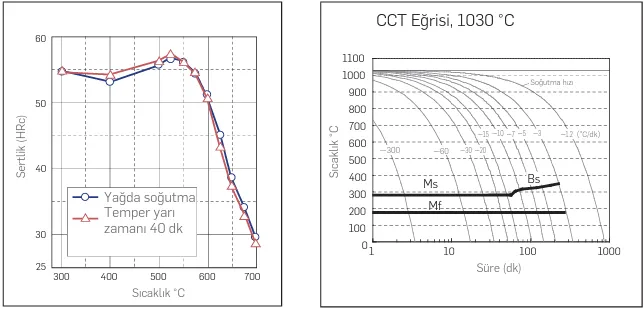

TEMPERING

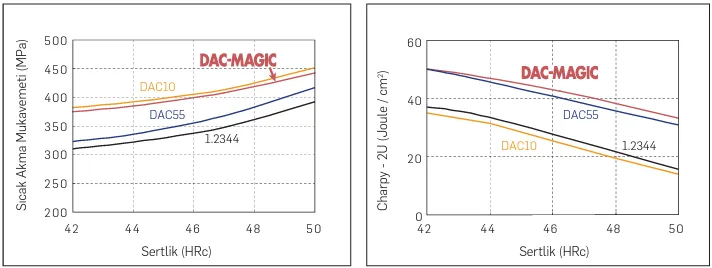

HIGH TEMPERATURE PROPERTIES

DAC MAGIC is a material with high temper resistance and also high toughness. These unique properties make DAC MAGIC a significant material in terms of thermal fatigue resistance.

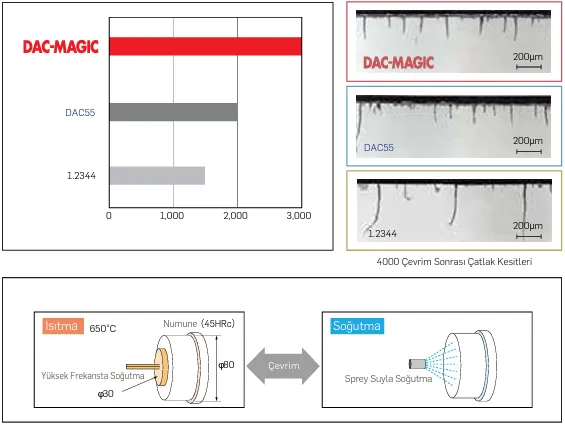

THERMAL FATIGUE RESISTANCE

DAC MAGIC has much higher thermal fatigue resistance compared to other hot work tool steels. Therefore, it especially extends the mold life in metal injection molds.