1.2367 (X38CrMoV5-3)

A hot work tool steel that retains its strength at high temperatures and performs better in hot work applications compared to 1.2343 and 1.2344 materials. For instance, it shows good performance in copper and brass extrusion applications. 1.2367 is supplied in a soft annealed state (200-230 HBW).

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 0,35 - 0,40 | 0,30 - 0,50 | 0,30 - 0,50 | - | - | 4,80 - 5,20 | 2,70 - 3,20 | 0,40 - 0,60 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2367 | - | X38CrMoV5-3 |

APPLICATION AREAS

- Metal injection molds

- Hot forging molds

- In metal injection molds as cores, pins, sleeves

- In aluminum extrusion molds

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 30,80 | 33,50 | 35,10 | |

| Temperature | 20-100°C | 20-300°C | 20-500°C | 20-700°C |

| Thermal Expansion | 11,90 | 12,60 | 13,10 | 13,50 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 730-780 | In Furnace |

| Stress Relieving | 600-650 | In Furnace |

| Hardening | 1030-1080 | Pressurized gas, air, oil |

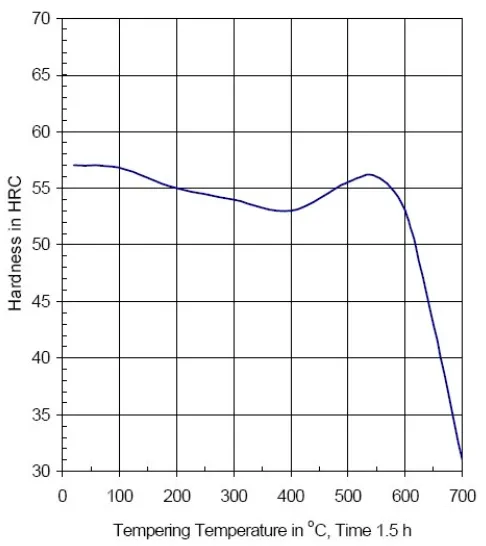

TEMPERING