1.2343 ESR (X37CrMoV5-1)

A hot work tool steel with better thermal conductivity than 1.2344, exhibiting high toughness. It can be used in all applications where 1.2344 material is used. 1.2343 ESR is supplied in a soft annealed state (210-230 HBW). As it is produced using the ESR (Electro Slag Remelting) method, it possesses high toughness. Due to this, surface cracks start to form later, and the progression speed of the cracks is slow.

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 0,34 - 0,42 | 0,85 - 1,20 | 0,2 - 0,50 | 0,025 | 0,002 | 4,80 - 5,50 | 1,20 - 1,50 | 0,40 - 0,50 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2343 | H11 | X37CrMoV5-1 |

APPLICATION AREAS

- Metal injection molds

- Hot forging molds

- Hot cutting blades

- Industrial blades

- Plastic molds

- Mold parts with chronic fracture problems

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 25,30 | 27,60 | 30,50 | |

| Temperature | 20-100°C | 20-300°C | 20-500°C | 20-700°C |

| Thermal Expansion | 11,40 | 12,40 | 13,10 | 13,30 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 750-790 | In Furnace |

| Stress Relieving | 600-650 | In Furnace |

| Hardening | 1000-1050 | Pressurized gas, air, oil |

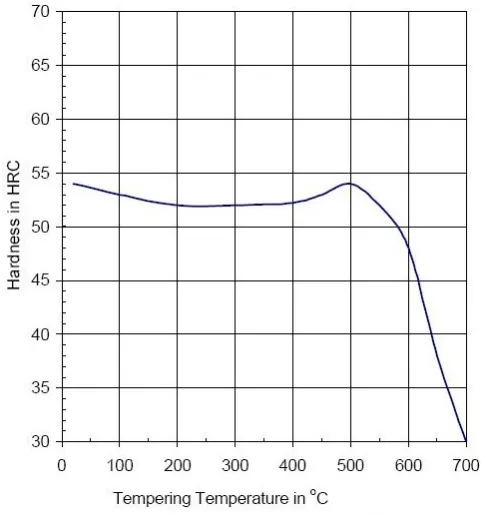

TEMPERING