1.2344 (X40CrMoV5-1)

A hot work tool steel that retains its mechanical properties and wear resistance at high temperatures. It's a standard material in hot forming molds. It possesses high tempering resistance and wear resistance. Hence, it is frequently chosen not only for hot work applications but also for plastic molds. 1.2344 is supplied in a soft annealed state (210-230 HBW).

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 0,35 - 0,42 | 0,80 - 1,20 | 0,25 - 0,50 | 0,025 | 0,002 | 4,80 - 5,50 | 1,20 - 1,50 | 0,85 - 1,15 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2344 | H13 | X40CrMoV5-1 |

APPLICATION AREAS

- Extrusion tools

- Hot forging molds

- Aluminum, Zamak casting molds

- Hot cutting blades

- Plastic molds

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 25,60 | 28,40 | 29,40 | |

| Temperature | 20-100°C | 20-300°C | 20-500°C | 20-700°C |

| Thermal Expansion | 10,80 | 12,30 | 13,00 | 13,50 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 750-800 | In Furnace |

| Stress Relieving | 600-650 | In Furnace |

| Hardening | 1020-1060 | Pressurized gas, air, oil |

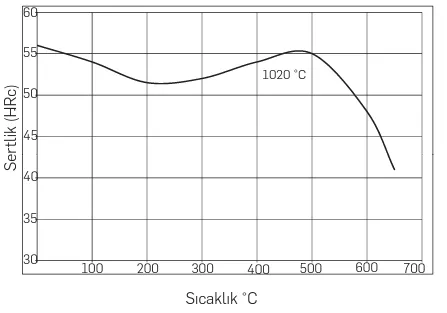

TEMPERING