1.2842 (90MnCrV8)

It is a medium-alloyed cold work steel containing approximately 1% carbon. It's also known as oil steel. It has a high hardening capability towards the core. Dimensionally, it is stable and has good compressive strength. However, its wear resistance is lower compared to 1.2379. It shows similarities to AISI 02 and 1.2510 steel.

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 0,85 - 0,95 | 0,10 - 0,40 | 1,90 - 2,10 | 0,03 | 0,03 | 0,20 - 0,50 | - | 0,05 - 0,15 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2842 | O2 | 90MnCrV8 |

APPLICATION AREAS

- In sliders and toolmaking

- Broaches, gauges

- Punch holders, punch plates, scrapers

- Cutting and forming molds with low production quantity

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 32,80 | 32,00 | 31,50 | |

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 12,20 | 13,20 | 13,80 | 14,40 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 680-720 | In Furnace |

| Stress Relieving | ~650 | In Furnace |

| Hardening | 790-820 | Pressurized gas, air, oil |

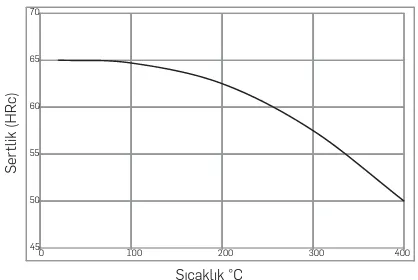

TEMPERING