1.2379 (X153CrMoV12)

It is a high-alloy cold work tool steel with high wear resistance and high strength due to its large and hard carbides. 1.2379 is supplied in a soft annealed state (~250 HBW). Due to its high alloying elements, the material can easily harden and can reach a hardness of 60-62 HRC after heat treatment. 1.2379 is also suitable for surface treatments like PVD/CVD.

CHEMICAL COMPOSITION (%)

| C | Si | Mn | P Max | S Max | Cr | Mo | V | W | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 1,45 - 1,60 | 0,10 - 0,60 | 0,20 - 0,60 | 0,03 | 0,03 | 11,00 - 13,00 | 0,60 - 0,80 | 0,90 - 1,10 | - | - |

STANDARD EQUIVALENTS OF THE MATERIAL

| DIN | AISI | EN |

|---|---|---|

| 1.2379 | D2 | X153CrMoV12 |

APPLICATION AREAS

- Cutting and forming molds

- Rolling, deep drawing molds

- Punching stamps and punches

- Profile and pipe rollers

- Swaging tools

- Slitting blades, plastic crushing blades, guillotine shears

- Cold extrusion tools

PHYSICAL PROPERTIES

| Temperature | 20°C | 350°C | 700°C | |

| Thermal Conductivity | 16,7 | 20,5 | 24,2 | |

| Temperature | 20-100°C | 20-200°C | 20-300°C | 20-400°C |

| Thermal Expansion | 10,5 | 11,5 | 11,9 | 13 |

HEAT TREATMENT INFORMATION

| Temperature | Cooling Medium | |

|---|---|---|

| Softening Annealing | 800-850 | In Furnace |

| Stress Relieving | ~680 | In Furnace |

| Hardening | 1010-1080 | Pressurized gas, air, oil |

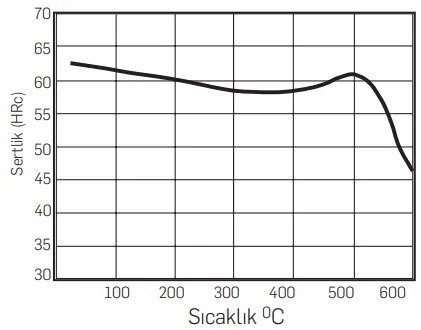

TEMPERING