SLD Magic

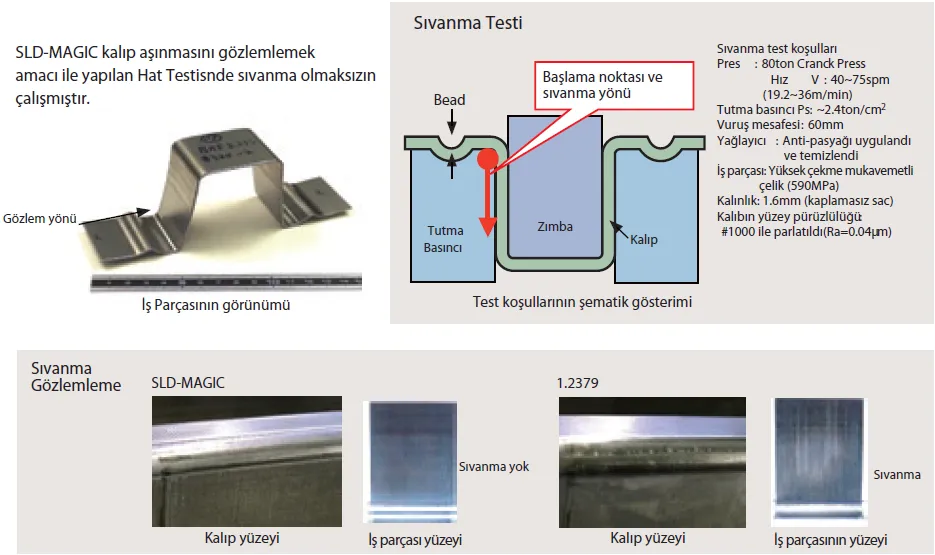

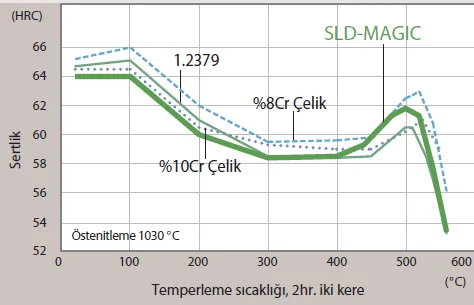

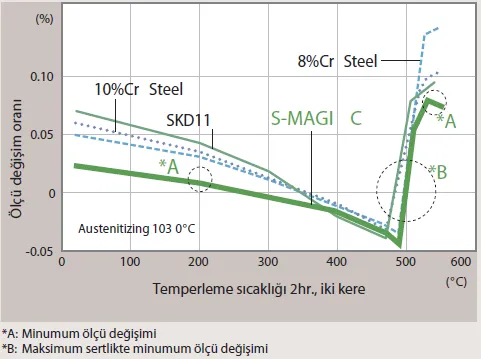

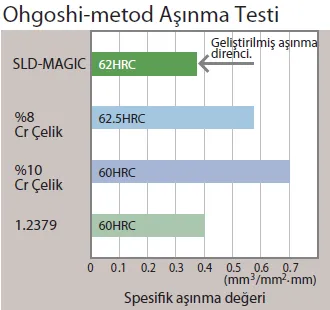

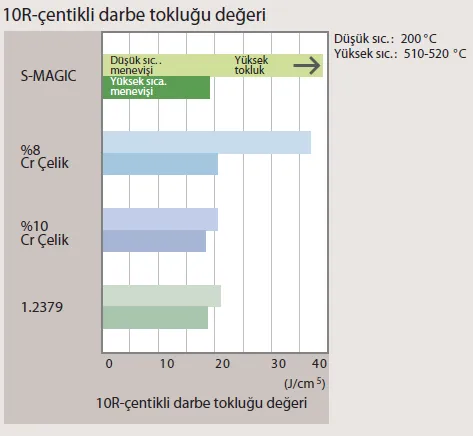

As a new generation of tool steel, SLD-MAGIC both extends the life of the mold and facilitates its manufacture. SLD MAGIC is supplied in a soft annealed condition (~255 HBW). It has higher toughness, wear resistance, and bending resistance compared to other cold work steels. Thanks to these features, it is an ideal material for those who want to achieve high performance in cutting, forming, and bending molds of materials such as high strength sheets, aluminum, and stainless steel. With its high hardness of 62 HRC, it increases wear resistance by approximately 35%. The adhesion rate between the steel and the coating layer after surface treatments (PVD-CVD, etc.) has been improved by approximately 30%. It facilitates the secondary machining process with minimal dimensional change during heat treatment. Its machinability has been increased by 35% compared to 8% Cr steels.

| Chemical Composition |

|---|

| Cr-Mo-V Alloy Patent Material |

| Standard Equivalents of Material |

|---|

| SLD MAGIC |

Areas of Application

- Cutting and Forming Molds

- Bending Molds

- Forming Rollers

- Crushing, Slitting Blades

- Punch Tools

| Physical Properties | ||||

|---|---|---|---|---|

| Temperature | 20°C | 200°C | 400°C | 600°C |

| Thermal Conductivity | 16,50 | 21,40 | 24,50 | 28,90 |

| Thermal Expansion | 12,20 | 12,20 | 13,10 | 13,50 |

| Heat Treatment Information | ||||

|---|---|---|---|---|

| Temperature | Cooling Medium | |||

| Softening Annealing | 830-880 | In Furnace | ||

| Stress Relief | ~680 | In Furnace | ||

| Hardening | 1000-1040 | Pressurized Gas and Air |

Tempering and Dimensional Change

Bending Resistance